SDC Weekly 119; A 200-Year Quest to Perfect the Double-Wheel Escapement; Watches and Living Well; Laurent Ferrier & HYT CEOs Exit

More on Breguet's Ingenuity, Insights from Art Basel and UBS Survey of Global Collecting 2025, Blade Runner Scene Recreation, Cocaine Kingpin in Dubai, A Short History of Bubbles and more!

🚨 Welcome back to SDC Weekly! I am travelling and may be slow to respond to comments etc… please bear with me! You’ll probably not care, but two people have been arrested over the theft of jewels at the Louvre. Surprised it took so long, given the amount of surveillance in major cities.

Admin note: The Unofficial Editor is unavailable after trying to edit on a camel’s back. It turned out to be a dry run, so click here to read this post online and ensure you see all corrections made after publishing.

If you’re new to SDC, welcome! If you have time to kill, find older editions of SDC Weekly here, and longer posts in the archive here.

Estimated reading time: ~32 mins

A 200-Year Quest to Perfect the Double-Wheel Escapement

I came across an article written by Derek Pratt in an old edition of the British Horological Journal, and I’d like to tell you about it.

Abraham Louis Breguet is reported to have said “Give me the perfect oil and I will give you the perfect watch!” The man had a point. In the early 1800s, watch oils were dreadful; they’d thicken up, run everywhere, or eventually just stop the watches from working. Every watchmaker knew this was killing their movements, but nobody had figured out how to build an escapement that didn’t need oil at all.

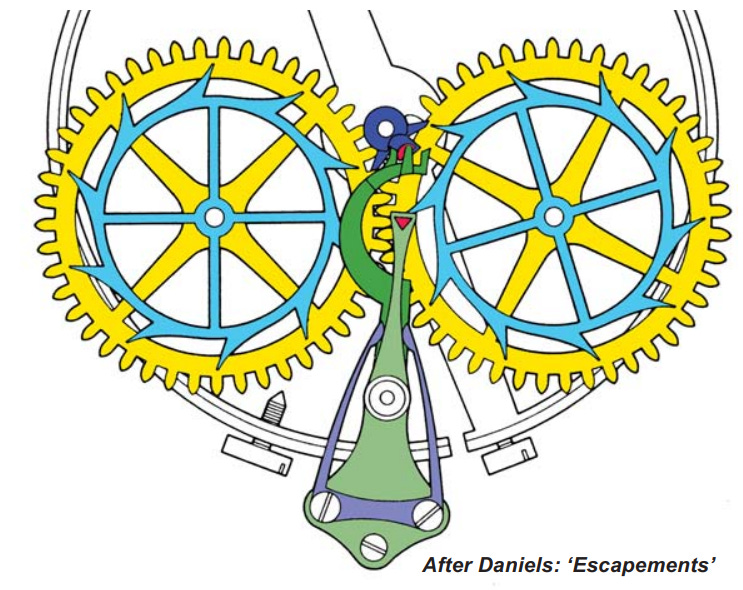

Breguet decided to have a crack at it. His solution was the échappement naturel or, natural escapement. The idea was to combine the best bits from two completely different escapement types. The lever escapement gave impulse to the balance twice per swing which is great for timekeeping, but it needed oil because the escape wheel pushed against pallets through sliding friction. Detent escapements touched the balance directly without needing oil, but only pushed once per swing instead of twice.

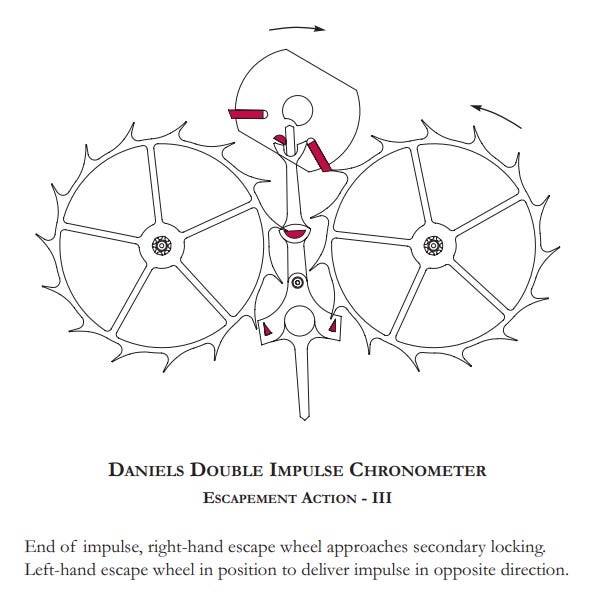

Above: Breguet’s échappement naturel. The left-hand escape wheel and pinion are driven by the train. The right-hand escape wheel is driven by the pair of toothed wheels from the left-hand wheel. Therefore both escape wheels move together but turn in opposite directions. A triangular locking jewel on the lever (shown in green) locks each wheel alternately. Unlocking is controlled by a ruby pin on the balance roller engaging a fork on the lever in a similar manner to that of a lever escapement. The balance is impulsed by one or other of the wing-like impulse pallets (dark blue). As shown, the balance is turning in a clockwise direction and the tooth of the right-hand escape wheel locked on the triangular pallet is about to be unlocked. The next tooth will impulse the balance. On the return vibration of the balance, the left-hand escape wheel will deliver the impulse in the anti-clockwise direction

Breguet’s natural escapement used two escape wheels spinning in opposite directions, each one giving a direct impulse to the balance. You can see the elegance straight away; this offered a double impulse which meant no oil was required between metal surfaces. He built this escapement into his early tourbillons, so clearly, he thought he’d cracked it.

Except he hadn’t. Two massive problems kept cropping up.

The first problem was that both escape wheels moved at exactly the same time. Breguet linked them together with gears, so when one turned clockwise, the other turned anticlockwise simultaneously. This created unhelpful inertia; just think about trying to push two heavy wheels at once, rather than taking turns with each one. The whole system was sluggish.

The second problem was a little more subtle... When you mesh two gears together, you actually need tiny gaps between the teeth so they can actually move. Only one wheel got power from the mainspring, and the other wheel just followed along. Those small gaps meant the follower wheel could ‘flutter’ slightly, and thus, it was never sitting in exactly the right position. Every time you moved the watch to a different angle, that flutter would change. Small variations in impulse inevitably led to timekeeping errors.

Breguet tried everything to remedy these problems. He made smaller-driven escape wheels with just three teeth to reduce weight, he used vertical pins instead of full wheel teeth… he basically experimented with all sorts of stuff, but he apparently never spotted another problem. The locking pallet had no ‘draw’ which I understand means that the lever wasn’t held firmly against its bankings while the balance swung freely. According to Pratt, the concept of ‘draw’ was still fairly new, so Breguet ‘missing it’ actually did made sense.

Eventually, Breguet gave up, abandoned his natural escapement, and went back to developing lever escapements instead (despite his hatred of oil). You can sense his reluctance in how he kept trying to trap oil in drilled or slotted escape wheel teeth; he knew lubrication was the weak link but couldn’t find a way around having to use it.

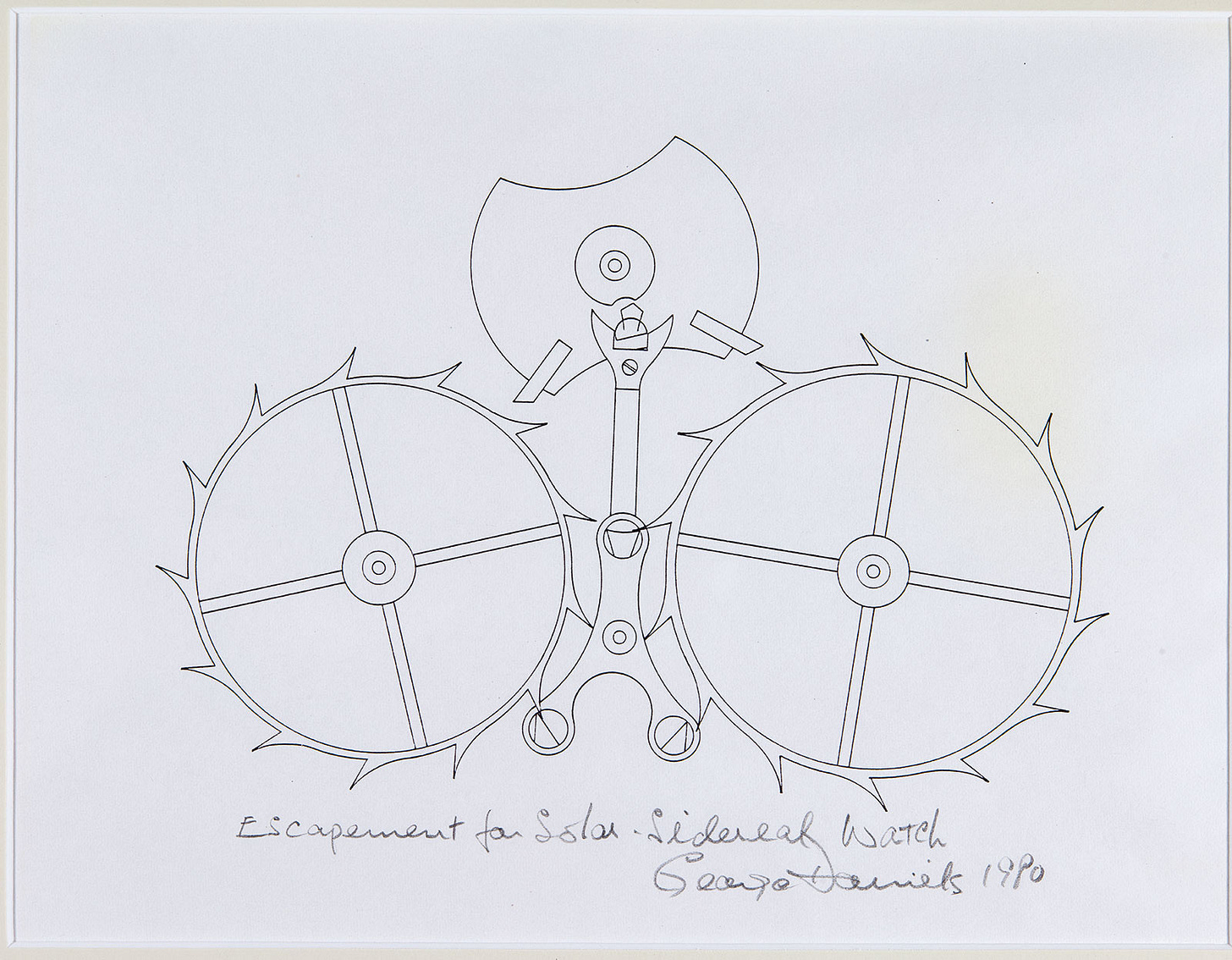

George Daniels takes another look

Fast forward to the 1970s, and George Daniels decided to revisit Breguet’s abandoned idea. Daniels had handled and restored more Breguet watches than probably anyone alive, and wrote the definitive book on Breguet in 1975. He obviously understood both the brilliance of the original concept, and also why it had failed.

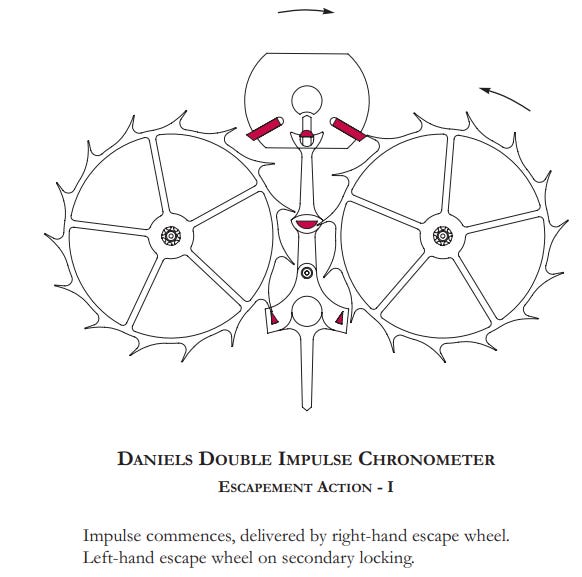

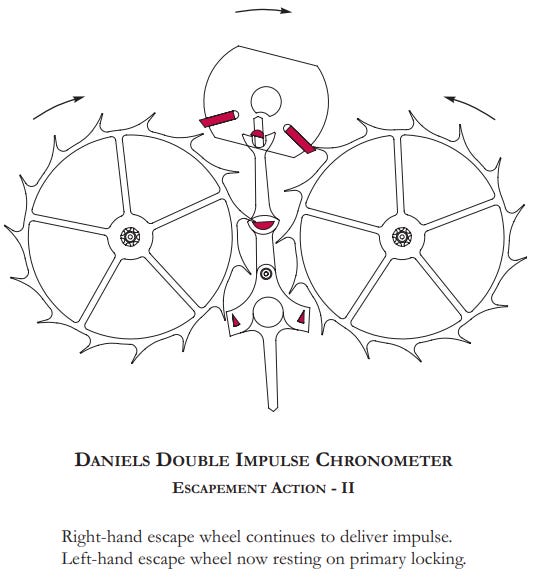

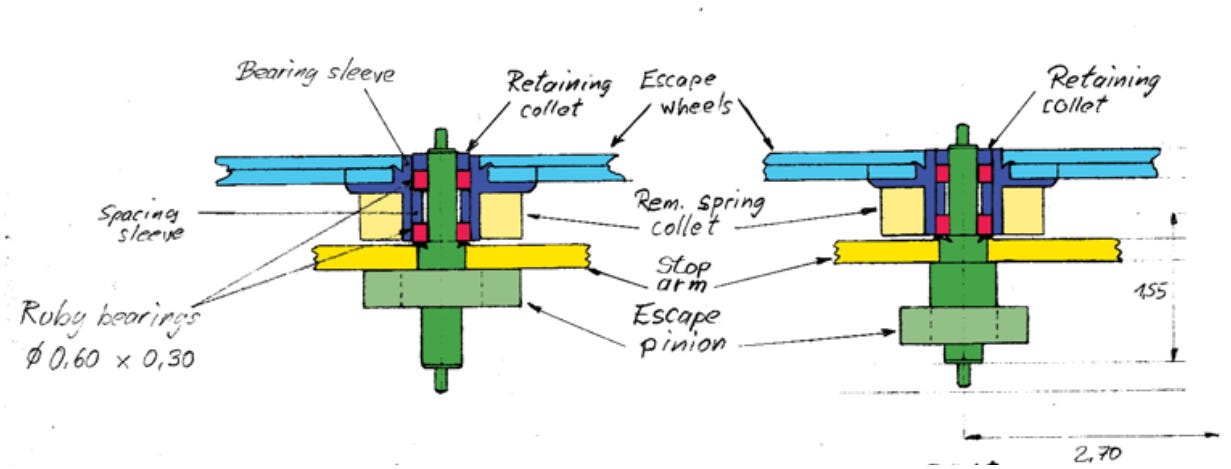

Rather than linking the two escape wheels with gears, he gave each wheel its own completely separate gear train1. Two independent power sources driving two escape wheels that took turns giving impulse to the balance. The wheels still spun in opposite directions, but now they moved alternately and not simultaneously.

This solved almost everything at once; the inertia dropped dramatically because only one wheel moved at a time, the flutter problem vanished because both wheels received power directly, and Daniels also added proper draw to the locking pallets, making the whole escapement secure and reliable. Most importantly, the balance still received a direct impulse from the escape wheel teeth with no oil required.

Derek Pratt, on his reaction to Daniels’ double-wheel escapement:

“I could immediately appreciate the considerable merit of this escapement but my first thought was that it was a pity that it could not be readily used in a tourbillon because of the independent trains driving the escape wheels. I started to think of ways around this problem and soon thought that two fixed fourth wheels, one with conventional teeth, the other with internal teeth, would give the necessary contra rotation of the escape wheels. However, it did not take long to realise that the problem was much more complex than this.”

Tourbillon problems

So Pratt’s point was that the two independent gear trains made is impossible to use this in a tourbillon, because a tourbillon carriage rotates as one unit… so how do you get two separate power sources into it?

Quoting Pratt:

“My original sketch on a scrap of paper has survived, complete with my comment at the time. I consigned the idea to the ‘needs further thought’ file in my mind but ‘took it’ out every so often for review. Many years passed but I simply could not just forget the idea because the escapement had really captured my imagination.”

Clearly, this question nagged at Pratt for years. He kept pulling the problem out for review, turning it over, getting nowhere concrete. Then during a session of what he calls ‘lateral thinking’, his brain served up a revelation. The exact words that popped into his head were something like: “It is not strictly true that the escape wheels are obliged to move at the same time; it is the escape pinions to which this applies.”

Remontoire saves the day

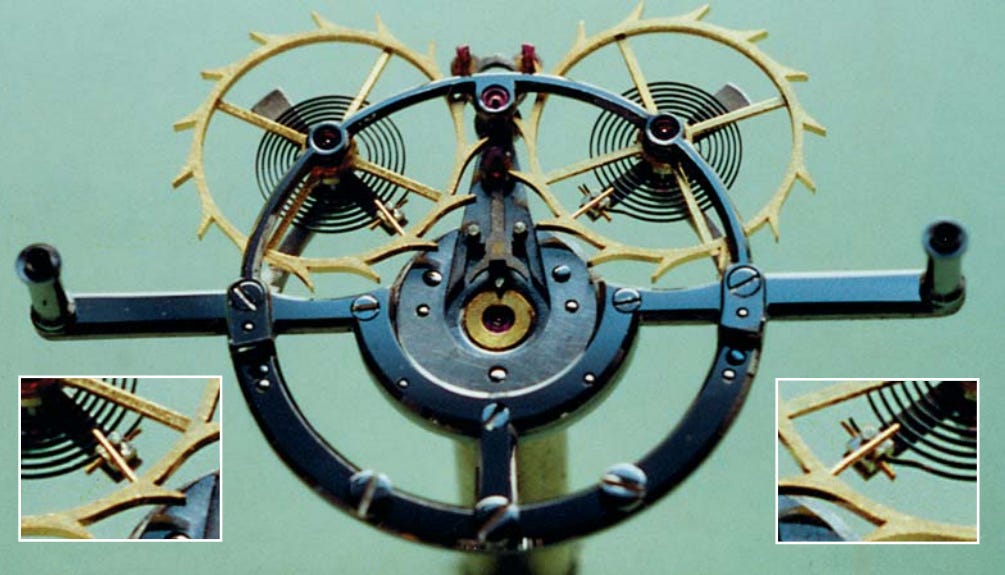

Pratt had already built several tourbillons with remontoire mechanisms. A remontoire sits between an escape wheel and its pinion, essentially adding a small spring that stores and then releases energy. The wheel and pinion aren’t rigidly connected – the pinion turns continuously while the wheel only moves when delivering impulse, with the spring connecting them. A control mechanism decides when to wind up that little spring again.

Pratt’s breakthrough was realising that in a tourbillon with twin escape wheels, the carriage itself could serve as the control mechanism. Both escape pinions could turn together (driven by the rotating carriage), but each pinion would connect to its escape wheel through a remontoire spring. While one spring delivered its stored energy to impulse the balance, the other spring was being wound up. Then they’d swap roles.

Each escape wheel now served two functions; at any given moment, one wheel was the impulse wheel (giving energy to the balance) and the other was the locking wheel (controlling when its remontoire spring would be rewound). After each impulse, the roles reversed. The carriage provided the connection between the two systems, and this solved the problem that had stopped him putting Daniels’ design into a tourbillon.

Pratt actually describes his design process in serious detail:

“I drew a layout of the escapement at 20X to explore the idea in depth and then made some cardboard escape wheels and a lever. I call this design-aid ‘CARD’, rather than ‘CAD’, which I do not use. The cardboard components are then correctly positioned on the drawing board with pins and the action of the parts can be readily investigated. I took this a stage further and animated the previously static parts with elastic bands to provide power and the resulting model is even capable of a few ticks, albeit with some hand assistance. The idea looked feasible and it was time to get to work in metal.”

Racing against a deadline

This was all happening in 1996, and at the time, Breguet (the company) announced a competition for innovation in mechanical horology, celebrating the 250th anniversary of Abraham Louis Breguet’s birth in 1747. The rules didn’t require a working watch, just an innovative concept, but Pratt wanted to actually build the thing.

Given he had less than a year, the pressure was on! The design problems seem to have been solved, but now came the hard work of making these microscopic components function together flawlessly.